COMMERCIAL SECURITY DEVICE MANUFACTURER | INDIANA | CASE STUDY SPECIAL: MASTERSEAL CR 195 EXPANSION JOINTS

Our customer appreciates our attention to the crucial details of an installation.

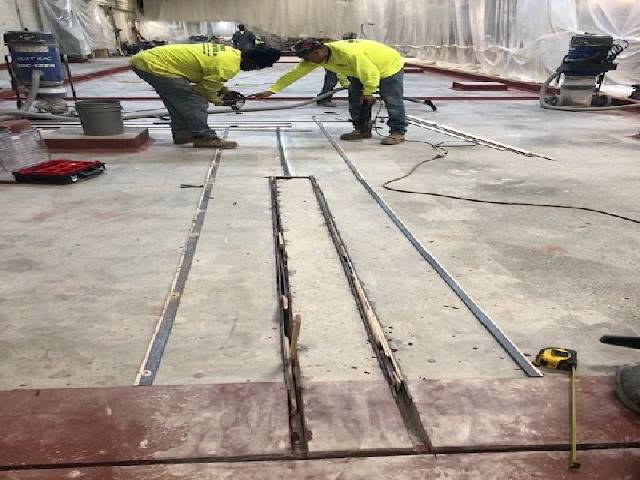

While working on our customer’s new flooring solution for an anodizing secondary containment area in their commercial security device manufacturing plant, the Surface Solutions, Inc. installation team must address the moving concrete slabs of the substrate.

First, we cut, clean and “honor” 124 L’ of footers, which means the expansion joints are filled and sealed differently from the rest of the 4,400-square-foot Ucrete installation. We do this by filling the moving joints with epoxy, applying a backer rod and finally sealing them with BASF MasterSeal CR 195 to allow for movement.

Because expansion joints typically require ongoing maintenance, the MasterSeal CR 195 is strategically applied in a white color so any potential separation is quickly visible and can be addressed immediately.

PRODUCTS

Epoxy | Backer Rod | MasterSeal CR 195

MARKET SECTOR

Electronics

LOCATION

Indianapolis, Indiana

CUSTOMER

Commercial Security Device Manufacturer

SQUARE FEET

124 L’ of Expansion Joints

TOTAL PROJECT TIME

7 Days

Installing Fillers and Sealers for Expansion Joints and Footers

Some may mistake sealers and fillers for concrete expansions joints as the same type of flooring solution, although each has a different purpose in the overall efficiency of the floor.

- Fillers and sealers are often installed after a concrete slab has a chance to shrink as much as possible.

- The rigid filler material supports the edge of a joint to allow for heavy traffic and wear.

- Before installing a sealer, put a backer rod in the bottom of the joint, which prevents the sealer from adhering to the joint and allows the sealer to stretch along with the movement of the joint. Adding a backer rod also reduces the amount of sealant needed for the sealer plug.

- In addition to preventing moisture and dirt from getting into the joint, the soft sealer material makes an impermeable bond with the concrete to accommodate its expansion and contraction. Sealers also prevent anything from penetrating the substrate or joint from below the slab, such as radon.

- Fillers and sealers should be checked periodically and repaired or replaced as needed.

Get a look at other successful industrial flooring system installations completed by Surface Solutions by visiting our Work Showcase.

About Surface Solutions, Inc.

Recognized as a top BASF Performance Flooring Master Contractor since 2012, recognized as experts in Ucrete® and MasterTop® solutions, Surface Solutions, Inc. is an independent industrial floor contractor specializing in seamless, polymer flooring systems utilizing the most trusted brands in the industry. As a Flow Resin STAR Contractor, Surface Solutions, Inc. is a leading provider of industrial flooring solutions for the Food & Beverage industry. From testing to consultation and complete installation services, Surface Solutions is your premier source of non-toxic, safe and environmentally friendly flooring systems, offering turnkey installations using only in-house personnel. All installations come with a complete single source warranty. To learn more about how Surface Solutions can help provide the highest quality industrial flooring solutions for your business, start your free custom quote.

NEED A FLOORING CONSULTANT?

Call us now at 317-388-8000 or click the button to plan your project today

COMPANY AWARDS